Our Valves - Delatite Valves

Delatite Valves Chemical Product Applications

Valves for Chemical & Petrochemical

When it comes to the demanding environments of the chemical and petrochemical industries, precision-engineered Valves are essential to ensure optimal performance, safety, and reliability. At Delatite Valves, we specialise in providing tailored Valve solutions designed to meet the unique challenges posed by corrosive, abrasive, and high-pressure conditions, among others.

Our comprehensive range of valves is specifically crafted to excel in chemical and petrochemical applications, including but not limited to:

- Corrosive Environments

- Abrasive Materials Handling

- Slurry Transport

- Extreme Pressure Conditions

- Catalyst Handling

- Chemical Processing

- Petrochemical Manufacturing

- Handling of Acetic Acid, Ammonia, Ethylene, Styrene, and other chemicals

- Integration with Pumps and Reactors

Each of our Valves undergoes rigorous testing and adheres to industry standards to ensure superior performance and longevity in the most demanding environments. Whether you require Valves for corrosive acids, abrasive slurries, or high-pressure systems, our specialised solutions are engineered to meet your exact specifications and operational requirements.

Our team of experts is committed to providing unparalleled technical support and assistance throughout every stage of your project, from initial consultation to ongoing maintenance and support. We understand the critical importance of reliability and efficiency in chemical and petrochemical processes, and we are dedicated to helping you achieve your operational goals safely and efficiently.

For more information about our specialised Valve manufacturing solutions or to discuss your specific application requirements in detail, please feel free to contact us. We look forward to the opportunity to serve you and exceed your expectations.

Delatite Valves Mining Product Applications

Valves for Metals and Mineral Mining

In the demanding environment of metals and mineral mining, where robustness, reliability, and efficiency are paramount, selecting the right Valve solutions is crucial to ensuring seamless operations. At Delatite Valves, we specialise in providing professional-grade valves engineered to excel in metals and mineral mining applications, including but not limited to:

- Mining Operations

- Slurry Transport

- Autoclave Systems

- Handling Heavy Slurry

Our comprehensive range of Valves including high pressure ball Valves is meticulously designed and rigorously tested to meet the unique challenges encountered in metals and mineral mining processes. Whether it's the abrasive nature of slurry transport or the high-pressure conditions within autoclave systems, our Valves are engineered to withstand the toughest operating conditions with unwavering performance and durability.

We understand that each mining operation is unique, and that's why we offer customisable Valve solutions tailored to your specific requirements. Whether you need Valves for ore processing, tailings management, or any other critical application within your mining operation, our experienced team is dedicated to working closely with you to deliver solutions that meet your exact specifications and operational needs.

With our commitment to quality, reliability, and customer satisfaction, you can trust Delatite Valves to provide the professional-grade Valve solutions you need to optimise your metals and mineral mining processes.

Delatite Valves Power Generation Product Applications

Valves for Power Generation

At Delatite Valves, we take pride in offering cutting-edge Valve solutions meticulously engineered to meet the diverse and demanding requirements of power generation applications. With a steadfast commitment to quality, reliability, and innovation, our Valves are trusted by power generation facilities worldwide to ensure seamless operations and optimal performance.

Our comprehensive range of valves is specifically designed to address the unique challenges encountered in power generation, including but not limited to:

- In-line Repairable and Automated Relief Valve Systems: Ensuring operational efficiency and safety through advanced Valve technologies capable of swift repair and automated relief functions.

- Solids and Ash-Handling Block and Isolation Valves: Providing robust solutions for handling solids and ash in power generation processes, ensuring reliable operation and minimising downtime

- Fossil Fuels: Offering specialised Valves engineered to withstand the extreme conditions associated with fossil fuel combustion, guaranteeing long-term reliability and performance

- Combined Cycle: Delivering efficient Valve solutions optimised for combined cycle power generation systems, enhancing overall energy production and efficiency

- Power Walkdown Inspection: Supporting comprehensive inspection and maintenance procedures with Valves designed for easy access and assessment, facilitating efficient power walkdown inspections

Whether you require Valve manufacturing for traditional fossil fuel-based power plants or cutting-edge combined cycle facilities, our experienced team is dedicated to providing tailored solutions to meet your specific needs. With a focus on innovation and customer satisfaction, we strive to exceed expectations and contribute to the success of your power generation operations.

Delatite Valves Refining Product Applications

Valves for Refining

At Delatite Valves, we understand the critical role that precision-engineered Valves play in the refining industry, where reliability, durability, and performance are paramount. With our unwavering commitment to excellence and innovation, we offer a comprehensive range of Valve solutions meticulously designed to address the specific requirements of refining applications.

Our Valves are engineered to handle a wide array of applications within the refining process, including:

- Isolation to Welded End Valves: Providing reliable isolation and seamless integration with welded end systems to ensure uninterrupted operation

- Catalyst Handling: Offering specialised Valve solutions capable of safely and efficiently handling catalyst materials critical to refining processes

- High Alloy Customised Valves: Tailoring Valves to meet the unique demands of high-temperature, high-pressure, and corrosive environments prevalent in refining operations

- Double Block and Bleed Designs: Enhancing safety and reliability with advanced Valve configurations featuring double block and bleed capabilities

- Delayed Coking, Deasphalting, Distillation, Gasification, Hydrocracking, Hydrotreating, Reforming, and Visbreaking: Offering specialised Valves optimised for each specific refining process, ensuring efficient and precise operation

Our commitment to excellence extends beyond product performance to encompass exceptional customer service and support. With a team of experienced professionals dedicated to understanding your unique requirements, we work closely with you to provide customised Valve solutions that meet your exact specifications and operational needs.

Whether you require Valves manufacturing for traditional refining processes or cutting-edge applications, you can trust us to deliver innovative solutions that optimise your operations and enhance productivity.

Our Valves - Models

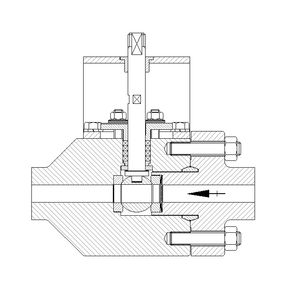

APV-LLK-2 Ball Valve

2 PIECE HIGH PRESSURE METAL SEATED BALL VALVES

This valve has been designed to be repairable if damaged and can be returned to as new condition.

Pressure Rating ANSI 3200# - 4500#

Sizes 12mm – 150mm

Ends: Butt Weld, Socket Weld Threaded, R.F. Flange, RTJ or any other end connection the customer may require

Shut Off: To MSS SP.61

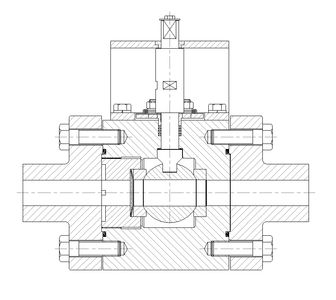

APV-LLK-3 Ball Valve

3 PIECE HIGH PRESSURE METAL SEATED BALL VALVES

This valve has been designed so that the centre section of this valve can be removed from the pipeline without the need to cut the valve out of the pipeline.

This results in major cost savings when it comes to valve maintenance.

Pressure Rating ANSI 3200# - 4500#

Sizes: 12mm – 100mm

Ends: Butt Weld

Body Gaskets Inconel

Shut Off: To MSS SP.61

.jpg/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:600,h:300,cg:true)

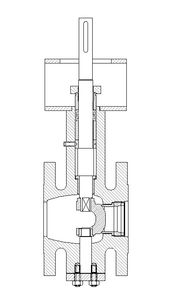

AMBV Australian Mining Ball Valve

FULL PORT FLANGED METAL SEATED BALL VALVES

Pressure Rating ANSI 150# - 2500#

Sizes: 25mm – 650mm

Ends: R.F. Flange, Threaded, Weld Ends, RTJ or any other end connection to suit the customers’ needs

Shut Off To MSS SP.61

AMCV Australian Manufactured Control Valve

ECCENTRIC OFFSET SLURRY CONTROL VALVES

These Delatite valves were designed for slurry applications with the option to carbide coat all internal surfaces including the valve trim.

Pressure Rating ANSI 150# - 600#

Sizes: 50mm – 300mm

Ends R.F,. Flange and Wafer

Shut Off: To ANSI Class IV

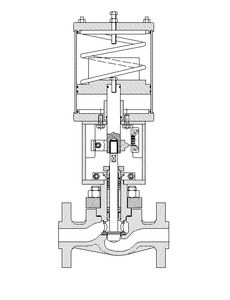

AGCV Australian Globe Style Control Valve

GLOBE STYLE CONTROL VALVES

This valve has been designed for general duty control service.

The valve has the option of a full size trim.

Pressure Rating ANSI 150# - 2500#

Bodies Globe and Angle

Trim: Full and multiple reductions

Sizes 25mm -300mm

Ends: R.F. Flange, Threaded, Weld Ends and any other end connection to suit the customer needs

Shut Off: To ANSI Class IV

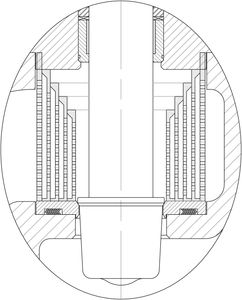

SEVERE SERVICE TRIMS

SEVERE SERVICE TRIMS VALVES

AGCV-DEL-ST

STEP TRIM CAVITATION CONTROL VALVES

DEL –ST Cavitation Control Trim

This trim has been designed to allow solid particles to pass through the valve trim.

Pressure Rating ANSI 150# - 2500#

Size: 25mm – 100mm

Body: Globe or Angle

Trim: Up to 7 steps

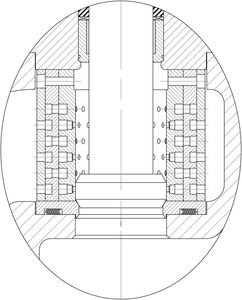

AGCV-DEL-LNT

NOISE CONTROL TRIM VALVE

This trim has been designed to reduce the noise levels in control valves.

Pressure Rating ANSI 150# - 2500#

Size: 25mm – 300mm

Body: Globe or Angle

Trim: Up to 4 stages

AGCV-DEL-CCT

MULTI STAGE CAVITATION ELIMINATION VALVES

The Trim has been designed to control cavitation in clean fluid service.

Pressure Rating ANSI 150# - 2500#

Size: 25mm – 300mm

Body: Globe or Angle

Trim: Up to 4 stages

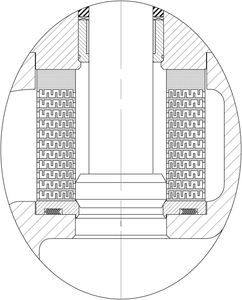

AGCV-DEL-CROC

MULTI TURN CAVITATION AND NOISE ELIMINATION VALVES

This trim has been designed to create a torturous path to control cavitation or reduce noise levels.

Pressure Rating ANSI 150# - 2500#

Size 25mm – 300mm

Body: Globe or Angle

Trim: Up to 8 teeth

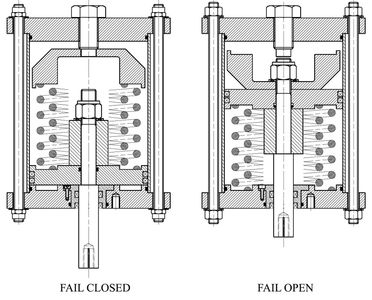

ACTUATOR VALVE

Valve Accreditations

Copyright © 2025 Delatite Valves - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.